1、 How to achieve rapid heat transfer and reduce heat loss:

1. Reasonably select the power of the heating wire, and pay attention to the position when winding the heating wire to evenly distribute the heat on the hot nozzle, in order to fully utilize the utilization rate of the heating wire. And enable rapid heat transfer and maintain heat balance;

2. The heating wire must be tightly attached to the hot nozzle to ensure heat transfer;

3. Copper is laid between the heating tube and the plate of the runner plate to ensure the fastest transfer of heat from the heating tube to the plastic material inside the runner.

How to reduce heat loss:

1. Reasonably design the structure of the hot nozzle; (For areas prone to heat loss, try to stay away from the heating element as much as possible)

2. Minimize the contact area between the hot runner and the mold as much as possible;

3. Try to use insulation materials between the hot runner and the mold.

2、 How to prevent glue leakage:

The mold and hot runner should be processed in place according to the drawings, especially the installation parts of the hot nozzle and mold.

The installation personnel must install according to the specifications:

1. Carefully check the dimensions of the mold and hot nozzle before installation;

2. During installation, it is necessary to use red lead between each matching part and install it according to the situation of the red lead;

3. Fill in the company's mold installation record form according to the actual situation.

3、 Hot nozzle or gate blockage

Reason:During injection molding, there may be foreign objects blocking the hot nozzle or gate, such as contaminated plastic melt.

Terms of settlement:Do not use tools, nails, or flames to clean foreign objects from the gate. To clean contaminated hot nozzles, it is recommended to remove them from the mold and heat them to the processing temperature of the plastic to remove molten material and pollutants.

To prevent pollutants from entering the hot nozzle, it is recommended to:

1. Wherever injection molded products are used, try to use pure raw materials as much as possible;

2. Store the raw materials in a clean and dry place;

3. Use a magnetic funnel;

4. Use the main feeding nozzle of the injection molding machine with filtering function;

5. Use an injection nozzle with filtering function.

4、 Difficulty in injection molding and filling:

Reason:

1. The melting temperature is too low;

2. Injection pressure too low;

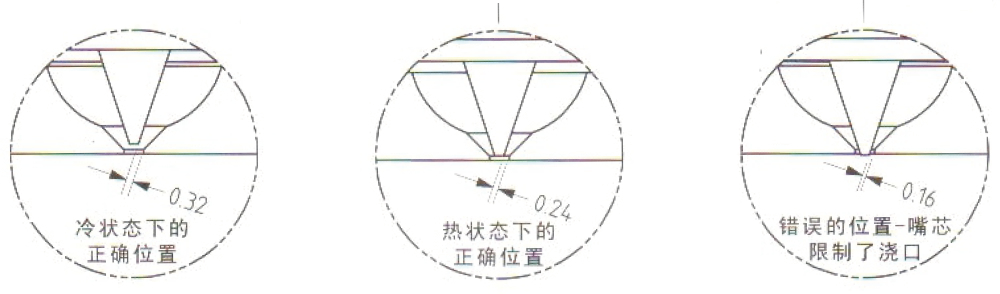

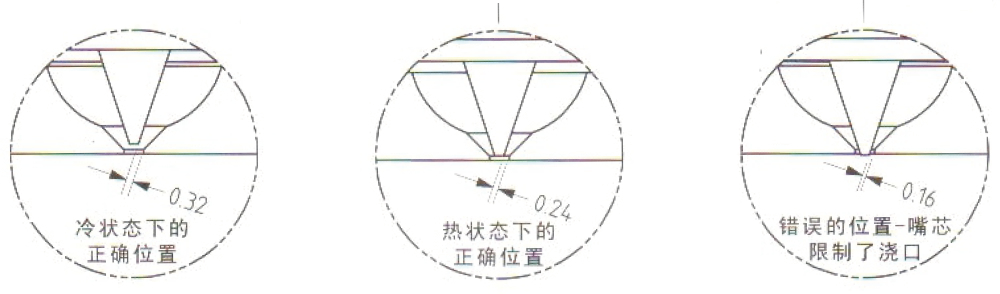

3. The gate is too small or restricted due to the position of the nozzle core too far forward in the hot nozzle (see attached figure);

4. The hot nozzle is too small;

5. The mold is too cold;

6. The diameter of the main feeding nozzle of the injection molding machine is too small;

7. The hot nozzle is blocked.

Terms of settlement: Check if the cavity of the hot nozzle is machined according to the required size of the hot nozzle. If the hot nozzle is too far forward, the front end of the nozzle will come into contact with the gate area of the cavity plate, resulting in a significant amount of heat loss at the nozzle.

If the size of the cavity is suitable for the hot nozzle, the temperature of the hot nozzle, mold, and splitter plate can be increased; Increase injection pressure; Increase the gate; Install larger nozzles; Increase the diameter of the main feed nozzle of the injection molding machine; Remove blockages.

5、 Hot mouth salivation or wire drawing:

Reason:

1. Insufficient rear suction;

2. The melting temperature is too high;

3. Excessive gate size;

4. Insufficient cooling of the gate;

5. Wrong selection of hot nozzle;

6. The hot nozzle is too far forward in the mold cavity, and the nozzle core is pushed forward to the gate area (see the attached figure above).

Terms of settlement:

Increase the temperature of the hot nozzle or mold; Check if the size of the hot nozzle cavity is correct; Reduce the gate diameter; Strengthen gate cooling; Contact the hot runner manufacturer to confirm if the selection is correct.

6、 Gate not working:

Reason:1. Heating wire failure; 2. Thermocouple failure; 3. The hot mouth is blocked.

Terms of settlement:Check/replace the heating wire; Check/replace thermocouples; Remove and clean the hot nozzle; Rework the hot nozzle cavity.

7、 Mouth rupture:

Reason: If the position of the hot nozzle in the cavity is too forward, the front end of the nozzle will come into contact with the gate area of the cavity plate.

Terms of settlement: Check and confirm whether the machining dimensions of the hot nozzle cavity are correct.

8、 Excessive flash on the workpiece:

Reason:

1. Excessive injection pressure;

2. Injection molding temperature is too high;

3. Poor fitting accuracy of the parting surface;

4. Insufficient locking pressure of the injection molding machine;

5. The template has warping.

Terms of settlement: Reduce injection pressure or holding pressure; Reduce the temperature of the hot nozzle, splitter plate, or mold; Increase the locking force of the injection molding machine; Replace the mold.

9、 There is cold material in the product:

Reason:1. Wrong selection of hot nozzle; 2. The hot nozzle head is too cold.

Terms of settlement: Contact the manufacturer of the hot runner to check if the selection of the hot nozzle is correct; Processing cold material dead corners on the back of the gate; Ensure that the contact area of the hot nozzle head is minimized.

10、 The temperature of the splitter plate cannot reach the set value:

Reason:1. The thermocouple is loose; 2. The thermocouple is broken; 3. The heating wire is open circuit.

Terms of settlement: Check if the thermocouple is loose and functioning properly; Check the heating wire circuit.

11、 The temperature rise of the splitter plate is too slow:

Reason:

1. Open circuit or loose wiring of the heating wire;

2. Insufficient air gap between the splitter plate and the mold;

3. Excessive cooling on the gasket;

4. Loose thermocouple.

Terms of settlement: Check all heating wires; Increase the air gap to at least 10MM or use insulation boards; Reduce the contact area between the gasket and the panel; Check the thermocouple.

12、 Unstable temperature of the splitter plate:

Reason: Thermocouple instability

Terms of settlement: Check the thermocouple.

XIIICylinder not working:

Reason:

1. No airflow;

2. Liquid flows into the cylinder;

3. The cylinder is stuck;

4. Insufficient system pressure;

Terms of settlement: Check for leaks or blockages in pipelines, installation pipes, and pumps; Check if there are too many bends in the feed pipe of the cylinder, which limit the feeding or control valve.

14、 Cylinder stuck:

Reason: 1. Non concentricity of cylinders, splitter plates, and nozzles; 2. Backboard overheating.

Terms of settlement: Check coaxiality; Increase cooling around the cylinder.

15、 Leakage of glue at the sealing ring of the closed valve needle:

Reason: The sealing ring of the valve needle in the splitter plate is too loose.

Terms of settlement: Check the diameter of the lining and air flow plate hole; Check the height of the sealing ring and diverter plate hole.

16、 Leakage of adhesive between sealing ring and valve needle:

Reason: 1. Wear and tear; 2. The flow index of the molten material is too high; 3. The pressure is too high.

Terms of settlement: Check the coaxiality of the system; Simultaneously replace the valve needle and sealing ring; Check the molten MFI; Reduce packing pressure.