The difference between a hot runner and a cold runner

Publisher: Administrator Date:2023-04-25

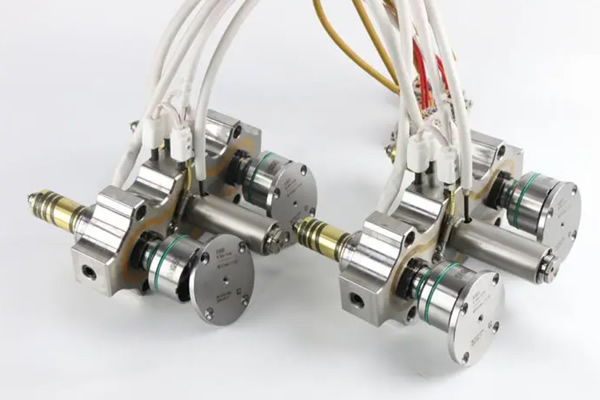

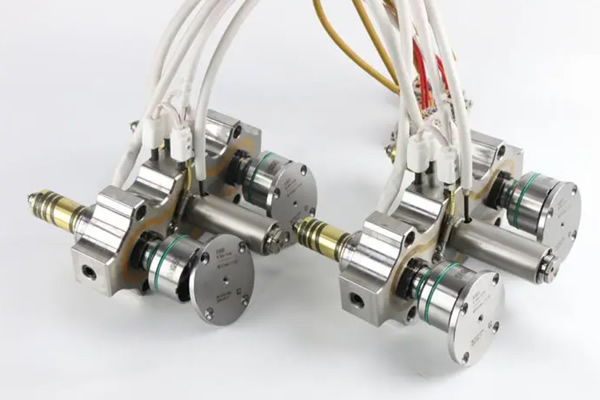

1. The hot runner adds functionality during the flow process.

A heating component system that injects melted plastic particles into the mold cavity. Hot runner mold is a new structure that heats the runner and runner of traditional mold or three plate mold, and does not need to take out runner and runner during each forming.

2. Hot runner can save plastic raw materials

In pure hot runner molds, there is no production cost due to the absence of a cold runner. This is particularly significant for expensive plastic application projects. In fact, the major international hot runner manufacturers have achieved rapid development in the era of high prices for petroleum and plastic raw materials in the world. Because hot runner technology is an effective way to reduce material costs and reduce material costs. The cold runner mold design is simple and widely used.

3. Hot runner reduces waste and improves product quality

During the hot runner mold forming process, the temperature of the plastic melt is accurately controlled in the runner system. Plastic can flow into each mold cavity in a more uniform and consistent state, resulting in parts of consistent quality. The parts formed by hot runner have good gate quality, low residual stress after demolding, and small deformation of the parts. So many high-quality products in the market are produced by hot runner molds.

4. The elimination of subsequent processes through hot runner is beneficial for production automation.

The overall reliability of the hot runner mold design has been improved. At present, major mold companies at home and abroad attach great importance to the design of hot runner plate and the research and development of pressure distribution, temperature distribution, sealing and other issues of the connecting part of the hot nozzle. The development and utilization of laminated hot runner injection molds is also a hot topic. Stacked molds can effectively increase the number of cavities, while the requirement for injection machine clamping force only needs to be increased by 10% to 15%.